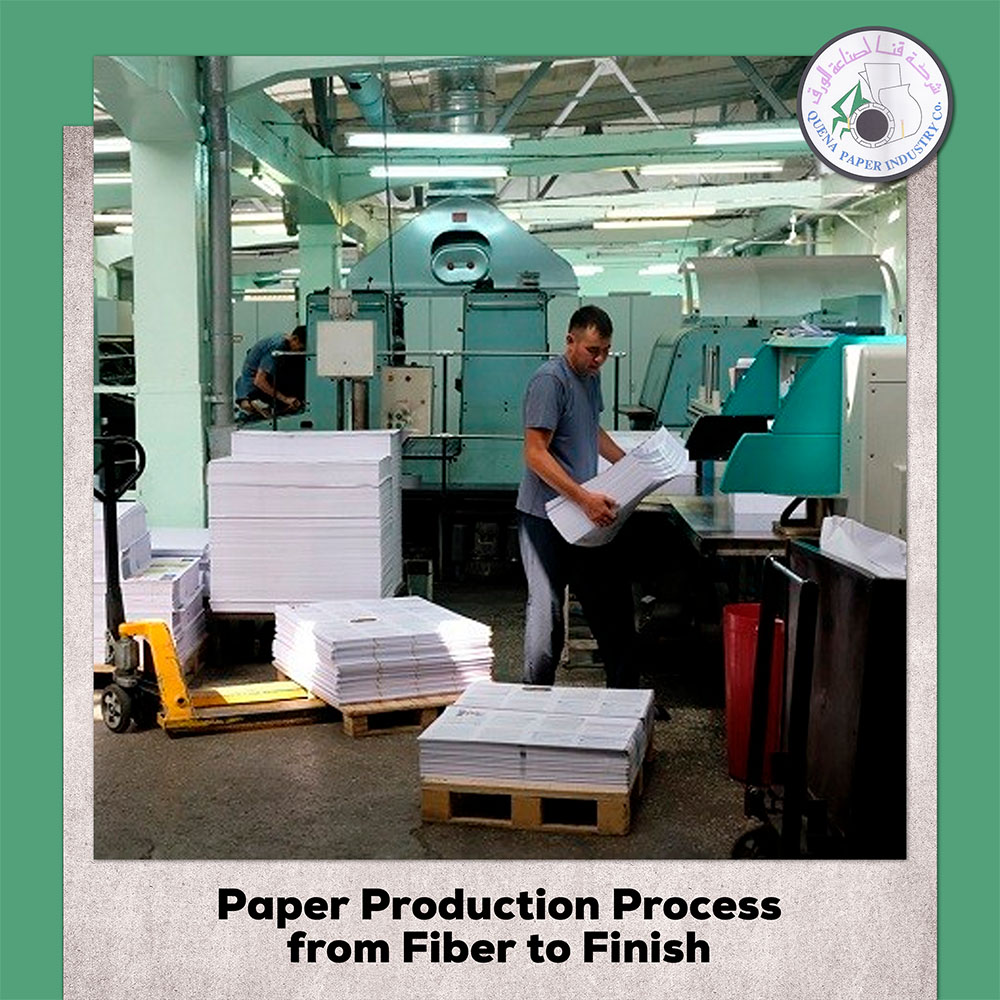

The paper production process is a fascinating journey that transforms raw fibers into the finished product we use every day. From humble beginnings as wood, rags, or recycled materials, paper goes through intricate steps to become the versatile medium we rely on for communication, education, and creativity.

Types of Raw Materials Used for Papermaking

Discover the diverse array of raw materials, including wood, cotton, and recycled paper, used in the papermaking process and their unique properties that influence the final paper product.

Sourcing and Preparing the Fiber

At the heart of papermaking lies the selection and preparation of the fiber. This section explores the various raw materials used, such as wood pulp, cotton, and recycled paper. Understanding the source and preparation of these fibers is crucial for ensuring the quality and characteristics of the final paper.

Mechanical Pulping vs. Chemical Pulping

Uncover the distinctions between mechanical pulping and chemical pulping techniques, exploring their respective advantages, disadvantages, and applications in the paper production process.

Recycling and Sustainability in Paper Production

The environmental impact of paper production is a growing concern. In this section, we delve into paper recycling processes and sustainable practices adopted by the industry to reduce waste and preserve valuable resources.

Sustainable Practices in Paper Manufacturing

Discover the industry’s efforts to adopt sustainable practices, including responsible sourcing, energy-efficient processes, and waste reduction, to ensure a greener future for paper production.

Innovations in Paper Manufacturing:

The world of paper production is continually evolving, driven by technological advancements and innovative practices. Here, we explore the latest developments and cutting-edge techniques that are shaping the future of paper manufacturing.

Advancements in Papermaking Technology

Stay abreast of the latest technological breakthroughs in the papermaking industry, from advanced machinery to digital innovations that are revolutionizing the way paper is produced.

Quality Control in the Papermaking Industry

Ensuring consistent quality is paramount in the papermaking industry. This section delves into the essential processes of testing and inspection employed throughout the paper production process to maintain high standards and meet customer expectations.

Testing and Inspection in Paper Quality Control

Explore the meticulous testing and inspection procedures employed to ensure the paper’s quality and conformity to specifications, maintaining customer satisfaction and confidence.

The paper production process is a fascinating journey that involves several intricate steps, transforming raw fibers into the finished paper products we use in our daily lives. Understanding this process can provide valuable insights into the significance of paper as a versatile and essential medium.

- Raw Material Selection: The first crucial step in the paper production process is the selection of raw materials. Different types of fibers, such as wood pulp, recycled paper, and cotton, are used as the base material for making paper. Each fiber type contributes unique characteristics to the final paper product.

- Pulping: Breaking Down the Fiber: Once the raw materials are selected, they undergo pulping, a process where the fibers are broken down into a pulp. Mechanical pulping and chemical pulping are two primary methods used, each with its advantages and applications.

- Papermaking Process: Forming the Sheet: After pulping, the papermaking process begins. The pulp is mixed with water to create a slurry, which is then formed into a continuous sheet using a paper machine. This wet end operation sets the foundation for the subsequent stages of paper production.

- Pressing and Drying: The formed paper sheet goes through pressing and drying stages to remove excess water and achieve the desired thickness. Proper pressing and drying are essential to ensure uniformity and strength in the final paper.

- Enhancing Paper Properties: Sizing and Coating: To optimize the paper’s performance for specific applications, sizing and coating processes are employed. Sizing is used to control the paper’s absorbency, while coating adds a layer to enhance properties such as smoothness, brightness, and printability.

- Cutting and Trimming: Preparing for Market: The large paper rolls are cut and trimmed to create standard-sized sheets suitable for various uses. This stage ensures that the paper products are ready for distribution and consumption.

- Recycling and Sustainability: With a growing focus on sustainability, paper recycling has become an integral part of the paper production process. Recycling paper reduces the demand for new raw materials and minimizes the environmental impact of paper manufacturing.

- Quality Control: Throughout the paper production process, stringent quality control measures are employed to ensure consistent product quality. Testing and inspection procedures help identify and rectify any deviations from industry standards.

By understanding the paper production process, individuals can appreciate the effort and craftsmanship involved in creating this essential commodity. Moreover, being aware of sustainable practices and recycling initiatives helps promote responsible consumption and environmental stewardship.